Roy Hill Mine - Building a Unified Digital Twin

Roy Hill, one of the world's largest integrated iron ore mining operations, faced the challenge of managing vast amounts of data across geology, drilling, infrastructure, and production. Traditional tools couldn't keep up with the scale, complexity, and need for real-time coordination.

To overcome these hurdles, Roy Hill relied on Voxel Farm's volumetric engine, the same technology that powers Voxel Space today, to create a unified, living digital twin of the entire mine.

The Challenge: Roy Hill's teams generated enormous amounts of spatial and operational data, but they were trapped in silos and difficult to reconcile.

This led to inefficiencies, blind spots, and safety concerns. Key challenges included:

01

Data Silos

Geological, drilling, and infrastructure data were fragmented across systems.

02

Surface-Only Models

Conventional 3D tools missed subsurface variability and time-based changes.

03

Operational Complexity

Coordinating extraction, processing, and logistics required a consistent view.

04

Team Alignment

Multiple departments working from different datasets caused inefficiencies and risks.

05

Geology Visualization

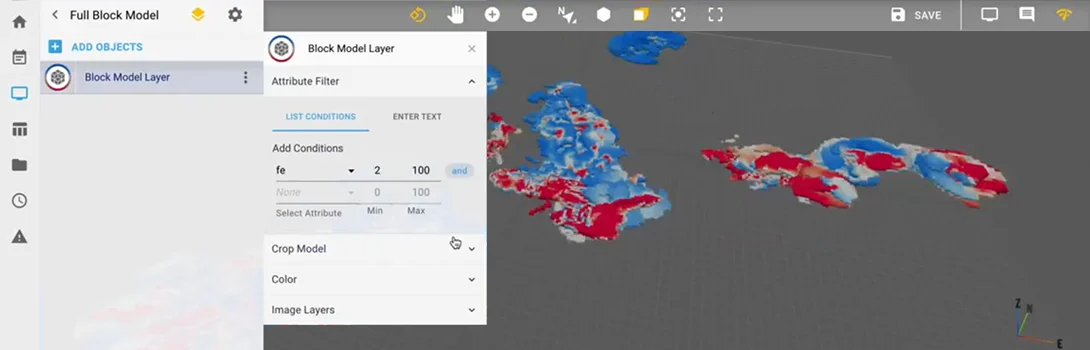

Complex grade blocks and ore bodies were too heavy for standard hardware.

06

Resource Estimation & Planning

Coarse block models and manual calculations led to imprecision.

07

Tracking Progress

Survey data often lagged behind real-world excavation.

08

Safety & Risk Management

Predicting wall collapses, water ingress, or weak zones was limited by incomplete data.

09

Scalability

Processing massive 3D datasets locally required expensive high-end machines.

The Solution

Voxel Farm Technology

Roy Hill implemented Voxel Farm's voxel-based system, technology that Voxel Space continues to advance, to unify their mining intelligence:

Unified Data Model Drill holes, seismic data, LiDAR, production records, and IoT feeds integrated into a single voxel grid.

Volumetric Operations View Beyond surface meshes, voxel models represented ore bodies, pit walls, haul roads, and tailings, in one coherent system.

4D Time-Aware Tracking Models updated continuously with historical and real-time changes, capturing ore movement and excavation progress.

Cross-Team Collaboration Engineers, planners, and geologists worked from the same living dataset, eliminating silos and ensuring consistent decisions.

Visualization of Complex Geology High-resolution voxel models ran directly in a browser, without requiring specialized hardware.

By adopting voxel-based intelligence, Roy Hill achieved:

Faster planning cycles with unified, always-current data grid.

01

Reduced waste and costs through more precise orebody modeling.

04

Improved collaboration with all teams aligned on one living dataset.

02

Safer operations thanks to early detection of weak zones and hazards.

05

Scalable access from desktop to browser, without heavy local computing.

03

Why It Matters

Roy Hill's digital transformation highlights how voxel-based intelligence is reshaping modern mining. By using Voxel Farm's volumetric engine, the company has unified data, improved collaboration, and enhanced safety across one of the world's largest iron ore operations.

And because Voxel Space builds on the same proven technology, it demonstrates how voxel intelligence can scale beyond mining to deliver a single source of truth, predictive insights, and measurable impact across industries.

Voxel Space is redefining mine intelligence with volumetric modeling, delivering unified data, real-time tracking, and scalable insight for the world's largest operations.

Explore the platform

Ready for Voxel Intelligence?

Request a Demo